X-UAV Mini Talon Build Compilation

| |

Introduction

This is a summation of my experiences building and flying the X-UAV Mini Talon. The component suggestions and build recommendations found here apply to the kit version and have all been fully test flown.

My Builds

To date I have built four of my own with number five waiting in a box and two for friends. In all cases I was looking for a balance between flight efficiency, reliability, fun and of course "the look". In the course of these builds I have created many 3D printable parts which can be found in my Mini Talon parts Catalog

MT#1 Information

| Original build page - X-UAV Mini Talon Build Number 1 On my first build I opted for the following gear:

|

|

| Ready for fun! |

For most of the Mini Talons life, the Sunnysky 2216-1250kv motor has been the favorite but my experience and some bench testing told me this was a marginally sized motor for this plane given its true power capacity and true continuous current ability. I knew I would be trying many different configurations which would get the AUW up so I opted for the slightly larger (+18g) Cobra 2221-940kv running 4S packs. As of February 2019, Sunnysky now makes a 2220 size motor that should be excellent given their build quality and cost.

I gave MT#1 to a very good friend after changing out some of the components and built #2 so that we could go fly together. MT#1 still flies great (Feb 2019)!

Lessons Learned

- 2 axis and 3 axis brushless gimbals are two heavy for this plane. It will carry the weight but it flies like a tank!

- The stock front wheel is worthless as it very easily is ripped from the fuse on a moderate landing

- The rear wood tail skid is also worthless and serves to rip the foam apart when it disintegrates

- The rear servo likage should be changed to use ball joints because of the high miss-alignment

- Skid protection is mandatory on this bird

MT#2 Information

| Original build page - X-UAV Mini Talon Build Number 2 On this, my second build I opted for the following gear:

|

|

| Ready! |

For the number two build I made a few minor changes in the fuse and did a LOT of 3D parts and Pan & Tilt development. One change that made a difference in pack and motor temps was to add spacers to the motor mount and open the motor mount center hole so that a lot more air could escape the fuse. I later created a 3D print of the motor mount which emulates the mount changes I made on this build.

Lessons Learned

- Don't go cheap!, my selection of the YEP 40A ESC resulted in the destruction of MT#2

- The L9R is not a long or even medium range radio set-up so I put DL back in

- The APM Mini 3.1 is a bit of a wild card in that it is more difficult to setup and doesn't really save that much weight

MT#3 Information

| Original build page - X-UAV Mini Talon Build Number 3 On build three which was a re-build of the destroyed #2 fuselage, I created a twin tractor setup with the following gear:

|

|

| A Twin! |

Build three was build two's resurrection and conversion to a twin. I always wanted a twin MT and the rebuild of the destroyed MT#2 was the perfect "nothing-to-lose" platform! Unfortunately, it had a short life due to a noob error on my part (see lessons below). It did have an annoying tendency to nose dive on launch which I never got to properly sort out due to its short life. I suspect this is caused by the very short tail moment and forward weight bias.

Lessons Learned

- NOOB! Do not power anything, like Pan & Tilt servos, from the RX unless you are certain the power feeding the RX can handle the servo load!!!

- The motors should have been a higher KV with smaller 6 x 4.5 props to get more plane speed and vertical performance

- Twin, counter rotating motors make the plane super stable but a chore to launch by hand. A bungee solves this

MT#4 (current) Information

| Original build page - X-UAV Mini Talon Build Number 4 On build four I opted for the following gear:

|

|

| Number 4! |

Build four was a new kit build. I developed a few more 3D parts and made the front cowl setup easier to change out Pan & Tilts, static mounts and other components. Built in May 2017, this plane still flies exceptionally today (Feb 2019)

Lessons Learned

- Nothing to add here (yet?!)

Kit Components

Every gram counts! With that in mind here are the raw (no glue) weights of the standard kit components:

|

Kit Assembly

First - It's all about Glue

The Mini Talon is made from EPO foam and my two favorite EPO glues are E6000 and Gorilla Clear Grip Contact Adhesive. These both work exceptionally well on EPO, stay flexible and have decent working times. Both should be cured for 24 hours for full strength. NOTE: THe E6000 glue will soften the EPO for a short period of time but when fully cured is fantastically bonded with no softness remaining.

Where to buy

I can find both E6000 and Gorilla Clear Grip Contact Adhesive here in the US at any department store or big box hardware store like Walmart or Home Depot

Other really good glues are UHU-POR and Beacons FoamTac although they are a bit harder to get and more expensive.

What about CA?

CA glues work fine but they are very brittle and subject to breakdown in high temperature/high UV areas (where I live). I only use CA if it is an emergency needing a super quick fix which I will typically re-do later with the above glues.

Glue I Avoid

The original Gorilla (expanding) glue is one I avoid with EPO foam. While it is a great glue, especially when you want to fill some "crash gaps", it does not really bond well to EPO and I have seen failed joints where it just peeled apart. On wood or EPP foam it is very good.

Fuselage Assembly

Wood parts

In MT#1 through MT#4 I have used the standard kit wood center structure with only a modification to make it exactly the correct width so that when the fuse is glued together, it doesn't "squish" the top hatch requiring lots of cutting and trimming to get the hatch to fit. The mod involves using thin strips of wood to space the side pieces farther out making the box wider.

|

I did not do a 3D print of the complete center structure because simply copying it would add a lot of unnecessary weight and no strength advantage. None of the designs I have seen to date offer any real advantage other than custom decks with vibration dampers that I think, and in my experience, are not needed. Since i got MT#5 I decided to continue to develop/refine some of my parts and I designed a center structure that is lighter, stronger and offers significantly better access to all internal components because it eliminates the front and rear plywood bulkheads.

|

| Center structure with extended deck |

On the motor mount I open the center hole and use M3 'T' nuts with 3-5mm spacers to get the motor spaced away from the mount. This allows significantly more air to exit the fuse and pass through and around the motor which improves motor cooling.

|

In my latest MT#4, I used a 3D printed mount that I designed to emulate the wood mount mods. The 3D print version is slightly heavier than the wood but it is a bit more versatile allowing two sizes of cross mounts to be easily bolted up.

|

The stock front deck plates are super easy to assemble and make the whole front end super strong. They allow you to screw down many different components like Pan and Tilts, VTx mounts, static camera mounts, etc. The weight of these wood parts is 37g (no glue) and they offer no aerodynamic improvement.

|

Since MT#2 I have used some of the 3D parts I have designed to accommodate my Pan & Tilts, Canopies and other bolt on components. All these parts can be found in the above referenced catalog.

|

Tail Feathers

The two tail vertical stabilizers (rudder-vators) I glue in with an additional wedge shaped support under the black fiberglass spar to stiffen them up. On one of the builds for a friend I actually bought some CF tube of the same diameter and cut them long enough to reach through the bottom of the fuse where they were glued and trimmed off on the outside. This made them very stiff however there was no noticeable difference in how the plane flew.

| 600px |

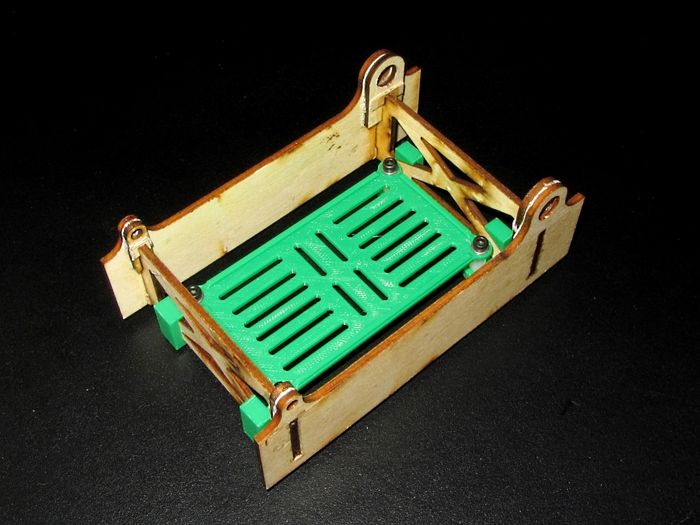

Skids

It became very clear to me on Mini Talon #1 that the front and rear need some skid protection. The stock wood rear skid is worthless and it lasted all of 2 or 3 flights. The stock front wheel (MT#1) lasted one flight. Some of this has to do with where I fly being all rock or hard pack dirt. So, my first attempt on MT#1 was to use a layer of 1.7oz Kevlar bonded with CA. This worked really well but it didn't last as long as I would have liked so I designed a front and rear skid to be printed and glued on.

|

|

These skids have been modified a few times but are damn near indestructible and don't add too much weight. They are both glued on with E6000. The best material I have found for these is ABS as it is a little more flexible and is not bothered by UV light the way PLA is.

Component Placement

Many folks have decided to mount all their components before gluing the fuselage halves together but I find this to be completely unnecessary with the Mini Talon. It has ample room to work with after the fuselage is all glued up and making components permanently mounted doesn't fit with my personal need to constantly modify things :)

Below is a general layout diagram or where I put all the components in a typical build. The idea here is to keep the noise-makers at on end and the noise receivers at the other. I always use a hand-held RF spectrum analyzer to make sure my component placement isn't causing problems and this layout represents what has worked very well for me.

|

With regards to components, here are some quick rules of thumb I follow-

- * Always use motor wire extensions to keep the battery, ESC and power wires as short as possible

- More information - See "ESC's" below

- * Never put anything out on a wing unless it is absolutely necessary!

- I've seen almost 30 miles out with the above layout (nothing on the wings). If you plan to go farther than this or if you plan to use more than an 800mw VTx, then maybe but understand you are killing the wings efficiency and adding potential RF interference to your control system when you do this

- * Never bundle receiver wires (RX, GPS, Video, etc.) with servo and/or power wires

- Doing this will help avoid "unexplained" noise in your system

Electronics and Set-Up

Power System

It is no secret I like Cobra motors and my favorite for this plane is the Cobra 2221 size. I use this size as I like to be able to change the configuration of the plane with Pan and Tilts or other gear and this size motor has the power needed for these different configurations. I have flown both the 2221-16/940kv and the 2221-12/1250kv and found that while the 940kv motor is just slightly more efficient, the 1250 is a lot more fun. For motor selection, you may want to look at an article I did on this - X-UAV Mini Talon Motor Selection

|

| Chart from the motor selection article |

Why not the Sunnysky 2216-1250?

Nothing wrong with this motor at all, they are very well made and likely one of the best motors you can buy in this size. In my experience though and after lots of testing, a 2216 is not large enough in terms of *true continuous current/power for the long term on a Mini Talon unless you are always going to have a plane that is under 1500g AUW. If this is your case, by all means this is an excellent motor.

- True continuous power - Sunnysky publishes a "Max Continuous Current" rating of 28 amps for 30 seconds on the 2216-1250. This is NOT "continuous" current, it is a max current for a 30 second period which is actually cumulative. The true continuous current is closer to 24A based on ROA heat testing.

By comparison, the Cobra 2221-1250 will manage 32A true continuous current provided you have good motor cooling (see motor mount mods above).

ESC's

For ESC's, I have used many mostly with good success on the MT. On the less expensive side of standard ESC's I have use HobbyKing Blue Series and Plush. On the slightly more expensive side, Cobra and Hobbywing and on the crap side, YEP.

With the exception of the YEP, these units all worked well without issues and in all cases where it is allowed, I have programmed them for braking and low frequency for efficiency. Since these are likely to be susceptible to power issues I have used one or two Low ESR capacitors on the ESC battery input to help keep them healthy. Here is more information on why the capacitors and short battery wires are desired-

"Too Long Battery Wires Can Kill ESC"

The experience I had with the YEP (40A) was that it simply exploded taking out the APM power module, flight controller and ultimately the plane itself. This was after about 20 flights and happened after a long low speed cruise where the plane was consistently pulling around 4-5 amps. I bought the YEP to get the feature "Active Freewheeling" which should have helped to keep things cool but what I got instead was a very poor quality ESC.

As for conventional ESC's (non BLHeli types), Hobbywing makes an outstanding unit, the Flyfun V5 40A which comes with a very robust and discrete, 8/20A SBEC with three selectable voltage outputs that is electrically very clean and reliable.

For sizing, it is important to understand that the ESC must be sized a bit larger than the maximum current the motor and prop you have selected will demand. Many folks run "over-propped" setups which means the motor will demand higher current than the motors designed specification. This means the ESC must be sized to this higher value rather than what the motor manufacturer says is the max value. For a little more information on why this is important, even if you are "throttle managing" please see this article-

Aircraft Power Systems - The ESC

Props

I could spend many pages on props here but I will keep it short. The first thing you need to know is that the numbers on the props are not exact. That is, the diameter is a little variable and the pitch is theoretical. The Pitch number is supposed to represent the distance the prop will move forward in one revolution in a non-compressible fluid. It is a measured angle at 75% of the blade length and does not take into account the lift efficiency of the the blade shape and chord. All this means basically is, it's a good guess.

I like and use folders, specifically Graupner and Aeronaut folders. These two brands are very well made and have given me excellent service over the long term. They are almost perfectly balanced as purchased and easy to set up. No other folder brand has proven to be anywhere near their quality and reliability. Here is more information on how I set my folders up in pusher applications-

How To - Set Up a Pusher Folding Prop

If folders are not for you, the best props out there are APCe (A.K.A. Thin Electric), Graupner and Aeronaut Cam Carbon. For FPV, all others are not as good (IMHO!). Of course many reading this will disagree and that's OK. The main thing to know about props is "buy many and test, test, test"! Bench testing, which I have done extensively, does not hold a candle to actual flight tests and a prop that works great for me and my flying style might not be the best for you. Understand too that for fairly low speed long distance flight efficiency, a deeper pitch prop is desirable. This is because it costs far more power to create too much thrust than it does to create too much prop speed. So a 9x7 on the MT will likely work better than a 10x5. These two props pull about the same power and RPM at WOT but the 9x6 will fly the plane more efficiently at low speed because it makes enough thrust where the 10x5, at the same plane speed is over-producing thrust and wasting energy. The aspect ratio (Diameter / Pitch) for our type of flying should be less than about 1.8 for best results.

Battery Packs

Almost as bad as props, battery packs will start many an argument. On the MT and other fixed wing FPV birds I have had excellent results using HobbyKing Multistar packs. These are low C packs that when taken care of, last a very long time, are relatively lightweight and not too expensive.

On the Li-ion side, I build my own welded packs and use these where I need a custom shape or size or just want to fly long and slow.

|

The claims by some that Li-ion's will get you huge gains in flight time and performance is generally marketing BS so buyer/builder beware! Li-ion packs do not deliver the equivalent punch (Voltage @ Current) that a Lipo will deliver and you have to be a little more careful not to over stress them for long periods. As for flight times, I get about the same flight time from a 7000mAh Li-ion as I get from a 6600 Lipo. The big difference is weight. With the weight of a 6600 MS Lipo at 544g, I can put together a 10,500 Li-ion that is only a little heavier, about 608g (+64g). The 10,500 will give me longer flight times (about 25% more) so there can be a good advantage by this measure. Another note here is the final fly-able voltage on Li-ion packs is ~3v per cell vs. 3.1v per cell for Lipo. Do not believe the marketing hype that you can fly a Li-ion pack down to 2.5v/cell, you won't make it home...

Battery Hold-down

For this I use two short pieces of velcro inside and a velcro strap which goes throught the fuselage using a 3D strap guide. this has worked well on this plane especially when the battery packs are nearly as wide as the fuselage.

|

Servos

We all have our favorite brand or type of servo for various reasons. In the MT's I have built I have used high end MKS, Hitec, Corona, Emax, Real and Fake TowerPro and HK servo brands. If I had to pick a favorite it would be either the Emax ES08MDII or the Corona DS929MG units. Both are very smooth, more than fast enough and with their metal gears, plenty strong for very long service in this plane.

Linkage

On the linkage I have used both the stock and Dubro 1/2A control horns. There is nothing wrong with the stock horns when glued in properly and my MT#1 is built with stock horns and still flies after 4 years!. In every case I use ball links on the tail control surface end (or both) to take care of high miss-alignment issues that are extreme on these control surfaces.

|

Parts I use-

- *Ball link - 2mm Swivel Ball Link

- *Rod - 2mm Threaded Rod

- *EZ Link - 2-56 EZ Link

As for control surface travel, I set the MT up with the following mechanical limits (radio endpoints at 100%)-

- *Elevator - +/- 8mm

- *Ailerons - +/- 12mm

You can certainly add more travel than this if you like to do a lot of sport/aerobatics but for a long range set-up, more travel can affect the smoothness and efficiency of your flight controller when in a stabilized mode.

Flight Controller

For flight controllers, I have tried many on the Mini Talon but I always come back to APM. These are what I have used (so far):

- 1. APM 2.8

- 2. APM 2.6

- 3. APM 3.1 Mini

- 4. Omnibus F4 (inav)

- 5. Omnibus F4 Pro (inav)

- 6. Eagle Tree Vector

- 7. Pixracer

- 8. Matek F405-wing

Without question the best on this list (as of this writing) is the Matek F405-wing. Loaded with the latest APM firmware, it performs for me better than any of the others. Further to this it has all the on-board power needed for all servos, peripheral components and video equipment as well as having an on-board OSD and power module. Because everything is on-board it also saves more than 75 grams over the Vector or other APM units I have tried.

|

GPS Module

The GPS module is a radio receiver which needs to be located away from the VTX and in some cases the RX when the RX has high power telemetry capabilities. As far as mounting, foam and thin plastic are invisible to GPS signals so you don't need to have the GPS antenna exposed, it can be buried in the foam or under a plastic cover. On a fixed wing aircraft, there is no need for a magnetic compass so a discrete GPS module such as a BN-180 or BN-220 are perfectly suitable.

Flying

Flight Times

Depending on your setup, flying style and how much "stuff" you have hanging off the airframe your flight time will vary greatly. The biggest enemy to this is drag with all up weight (AUW) coming in a close second. Also, since the power required to overcome drag goes up with the square of the speed, the plane needs to fly slowly but fast enough to keep tit level.

Weight matters too! Since a heavier plane needs a higher angle of attack at a given speed, the more weight, the more drag.

The best flight times I have flown have been on calm cool (60F - 80F) days flying a relatively slow mission with few large elevation changes. The times shown below were on different days and were done with near new packs. These were all done with the Cobra 2221-940 and Aeronaut 9x7 folder. The AUW of the plane was ~1100g (without the pack).

Multistar low 'C' packs

- 5200/4S - 438g ~68min

- 6600/4S - 544g ~82min

- 8000/4S - 660g ~92min

- 10,000/4S - 824g ~86min (flys like a pig)

18650GA Li-ion pack

- 7000/4S - 408g ~87min

My favorite pack is still the Multistar 6600/4S because of the power (punch) available and the fact it gives me more time in the air than I generally need.

Note: HobbyKing seems to have discontinued the Multistar brand but they still have low C packs available. In the case of the 6600/4S there is now a Turnigy version which is 12C and weighs ~50g more than the original Multistar.

See Also

- Mini-Talon on RC Groups

- Mini Talon Noses

- X-UAV Mini Talon Build Number 1

- X-UAV Mini Talon Build Number 2

- X-UAV Mini Talon Build Number 3

- X-UAV Mini Talon Build Number 4

- Parts Catalog - Mini Talon

Project 3D Print Files

The following are the 3D print ZIP files shown in this build.

- TBA

Some of the Vendors I used for this project

Comments? Questions?