Heavy Duty Pan and Tilt

![]()

© Mark Qvale - September, 2016

| |

| Big and Smooth |

Introduction

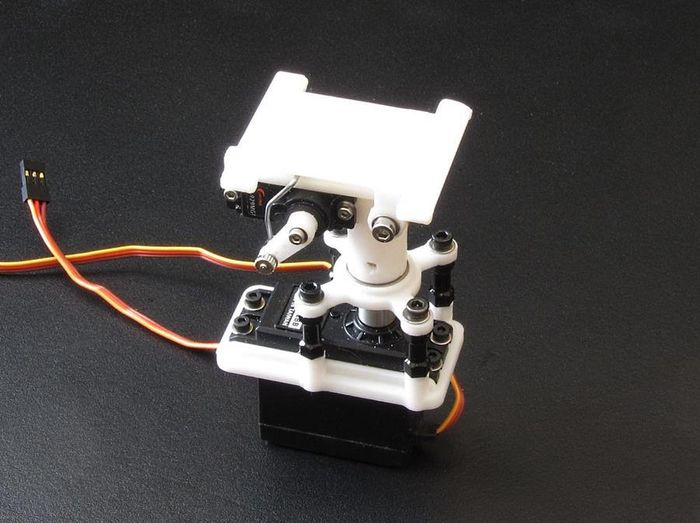

When I decided to put together a pan set-up for my big Talon to carry a 2 axis brushless gimbal, I went looking for components that I could buy to build a stout 360+ degree pan mechanism that didn't need gears, belts or extra linkage parts and I found the components I needed in a company called Actobotics. This project then is an extension of that earlier work on my big Talon and some of the work I put into the Mini Talon.

After buying and building several Pan and Tilt set-ups I got tired of how cheaply the purchased ones were and how flimsy most were. The biggest problem has always been the pan axis is simply never robust enough. When I did find something that was strong enough (for me) it was always too heavy and too expensive or presented too much wind area.

With the Actobotics Pieces, their Futaba servo coupler and bearing plate, I was able to build a raised bearing that made the servo connection very strong. This structure keeps all the stresses off the servo shaft and its bearings and elliminates unwanted motion or wobble.

|

| Base unit showing Coupler and Bearing plate |

I've added to this a turret and tilt mechanism which I have modified many times.

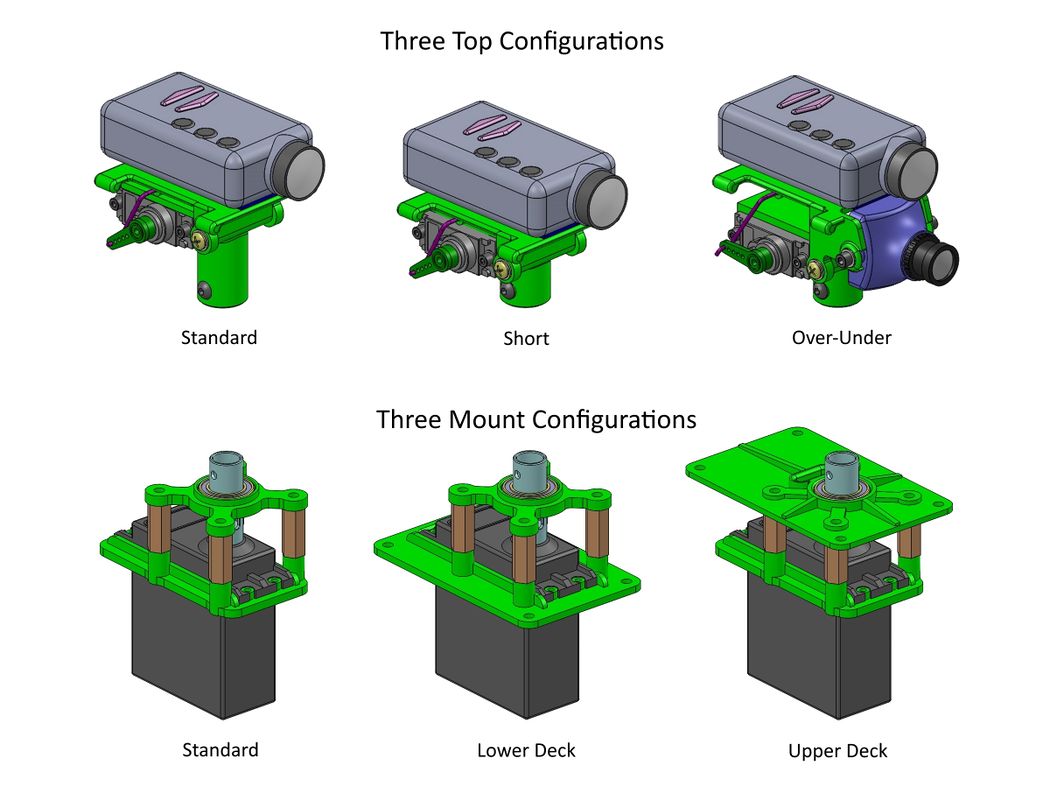

Tilt Configurations

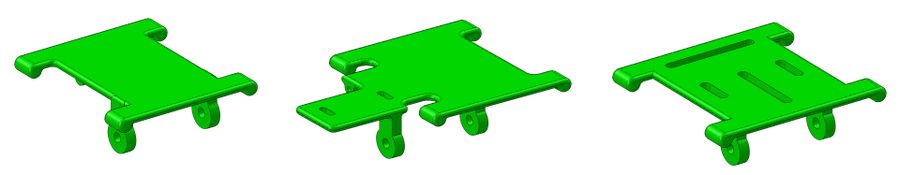

Because I always seem to need something different for every plane I've ended up with several versions of this idea. Most of my planes only require the ability to look down and around so there are three different camera mount plates.

- Standard Mobius/Runcam mount

- Dual Side-by-Side Camera Mount

- Misc Camera mount

|

| Three Standard Camera Mounts |

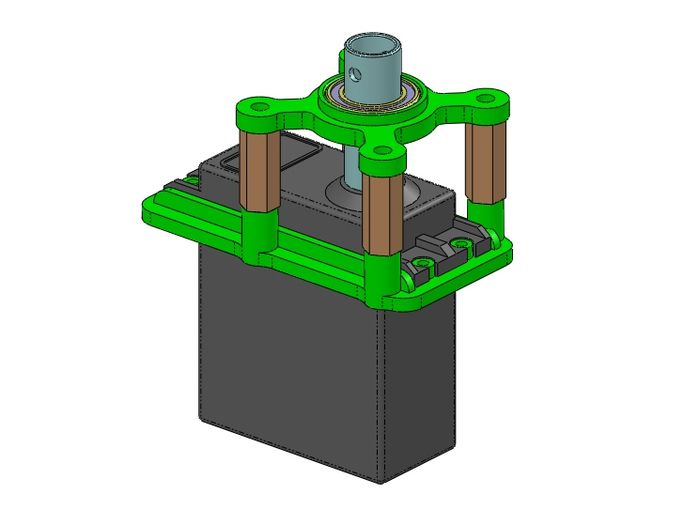

Added to this I have made two different turrets including a short version which, with the over-under set-up can look both up (20 deg) and down (-42 deg). With two turrets and three mount options there are nine different configurable set-ups for this P&T

|

| Lower and upper unit configurations |

Notes on Standard Configuration

- Aluminum servo coupler can be slotted to run up to 5 wires from the camera deck down to below the bearing plate. (see "Parts Prep")

- Camera plate nylon pivot screws must be cut to tighten against each other but not too tight that they lock-up the camera plate.

Notes on Over-Under Configuration

- Aluminum servo coupler can be slotted to run up to 5 wires from the camera deck down to below the bearing plate. (see "Parts Prep")

- Camera plate nylon pivot screws must be cut to tighten against each other but not too tight that they lock-up the camera plate.

- Designed around HS1177 FPV camera from Surveilzone

Parts and Specifications

Parts

Bottom Unit Printed Parts

- GWS Servo Plate

- GWS Servo Deck Plate

- Bearing Plate

- Bearing Deck Plate

Top Unit Printed Parts

- Tall Turret

- Short Turret

- Std Mobius Mount

- Std Dual Camera Mount

- Std Misc Camera Mount

- Over-Under Camera Mount

Servos

- Pan - GWS S125-1T (25 tooth)

- NOTE: The GWS S125-1t servo can be found with both a 23 tooth and 25 tooth spline. The 23 tooth spline was discontinued by GWS in 2014 but there is still lots of inventory out there. The 25 tooth which is identical to Futaba, must be found for this project.

- Tilt - 9g/120 Degree servo

- NOTE: This project was designed using a Corona DS929MG servo. While this servo works very well it is heavy at 14.1g. Most "9g" size servos should fit with small adjustments.

Hardware

- 1x Actobotics #525142 25t Futaba Servo Extension (Coupler)

- NOTE: For those not in the US, the US supplier has given me the website which identifies their sellers outside the US:

- NOTE: For those not in the US, the US supplier has given me the website which identifies their sellers outside the US:

- One such seller, StepLab, has commented on my Thingiverse page they have the parts for this project.

- One such seller, StepLab, has commented on my Thingiverse page they have the parts for this project.

- Alternatively, you can also print a coupler which fastens to a servo wheel. This part, Futaba_Servo_Coupler_v2.stl, can be found below and is now included in the download. It is not nearly as strong as the aluminum piece and must be very accurately printed to work.

- Alternatively, you can also print a coupler which fastens to a servo wheel. This part, Futaba_Servo_Coupler_v2.stl, can be found below and is now included in the download. It is not nearly as strong as the aluminum piece and must be very accurately printed to work.

- 1x 0.375"ID x 0.625"OD x 0.156"L Ball Bearing w/dual shield

- 1x 3" x 0.047" Steel Wire

- 1x 25mm x 45mm x 4mm Align PU-Gel Pad

Fasteners

- 2x M3 x 20mm Nylon PHS

- 4x M3 x 8mm SHCS

- 6x M3 Flat Washer

- 4x M2.5 x 8mm SHCS

- 4x M2.5 Flat Washer

- 4x M2 x 6mm SHCS

- 4x M2 Flat Washer

- 4x M3 x 15mm Aluminum Stand-offs

Mechanical Specifications

- Total weight with all hardware and a true 9g tilt servo - 93 grams

- Total weight without servos - 32 grams

- Pan rotaion - 385 degrees

- Tilt range, Std Camera Mounts - 0-70 degrees (down)

- Tilt range, Over-Under Mounts - -19 (up) to 45 degrees (down)

Parts Preparation

On any 3D print project, part preparation is key to a successful completion. The following images show what work needs to be done for this success.

Servo Plate/Lower Deck Mount

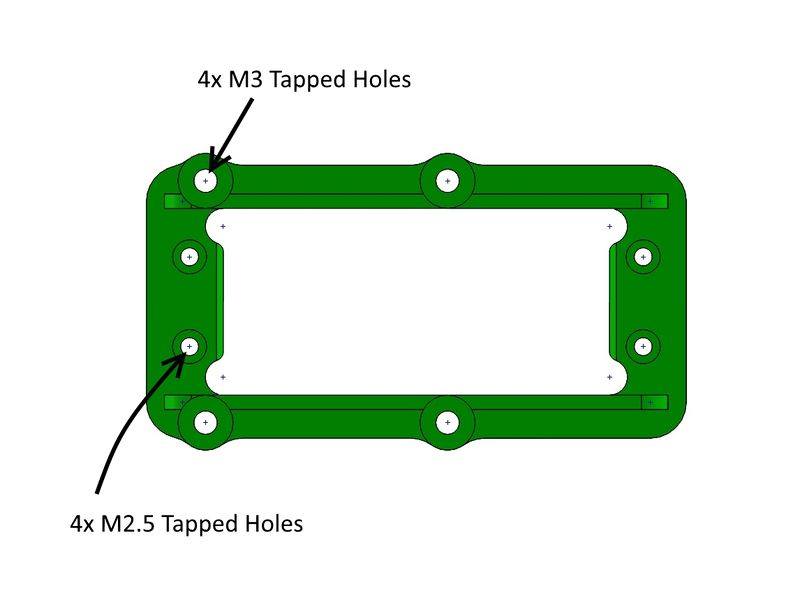

The servo mount needs 4 holes tapped to M3 and 4 holes tapped to M2.5:

|

Bearing Plate/Upper Deck Mount

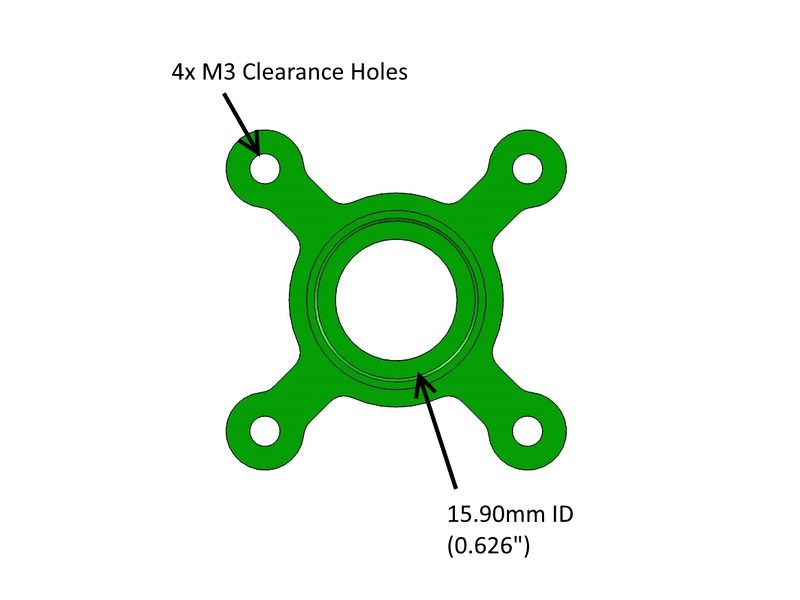

The assumption is your printer (or service) will hold the tolerance designed on an inside diameter. If your printer adds too much material you will need to make adjustments to accommodate the bearing OD which should push in with a little resistance:

|

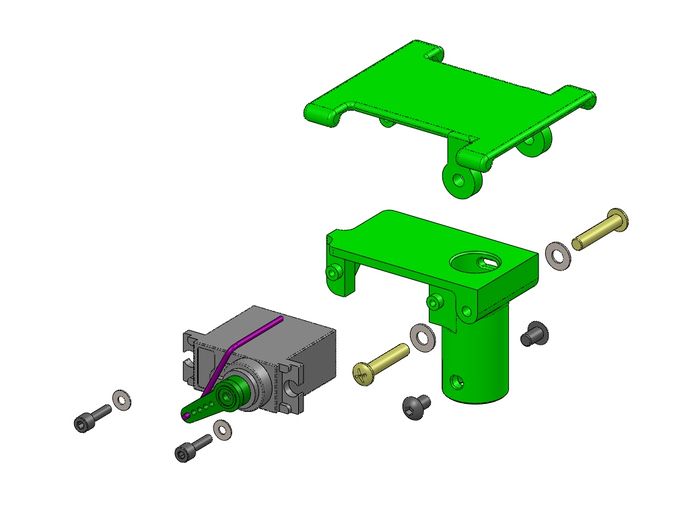

Turret Base

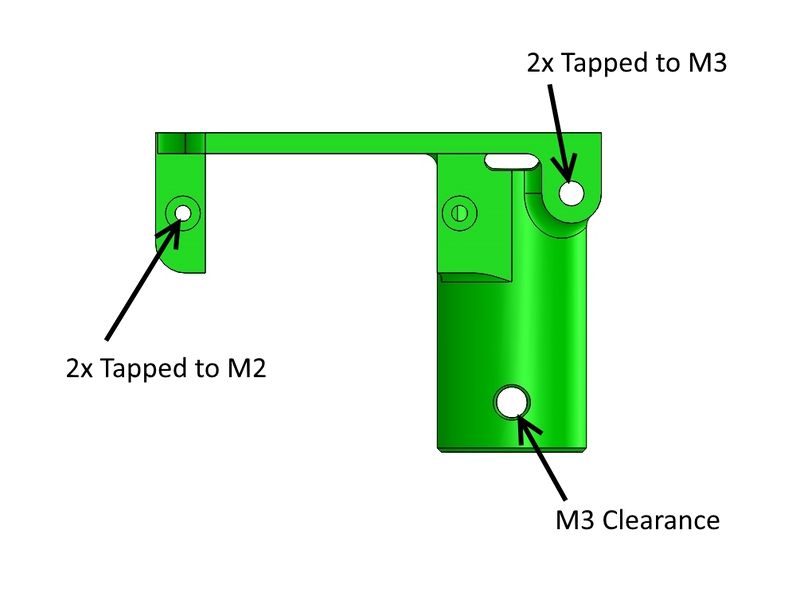

The Turret needs 2 holes tapped to M3 and 2 holes tapped to M2:

|

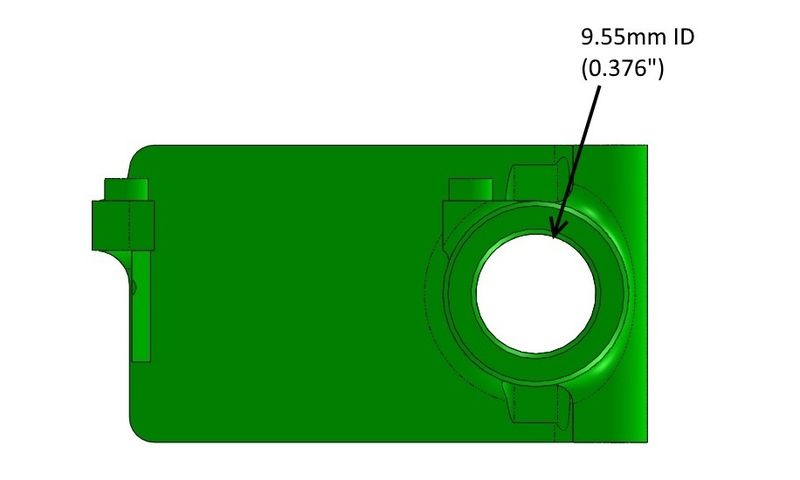

Like the bearing plate, the assumption is your printer (or service) will hold the tolerance designed on an inside diameter. If your printer adds too much material you will need to make adjustments to accommodate the coupler OD (0.375") which should push in with a little resistance:

|

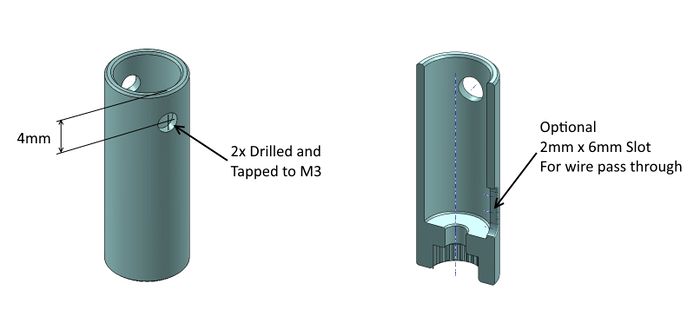

Servo Coupler

The Servo Coupler needs 2 holes drilled and tapped to M3. Optionally you can cut a 2mm x 6mm slot to pass wires from the camera plate down below the bearing plate.:

|

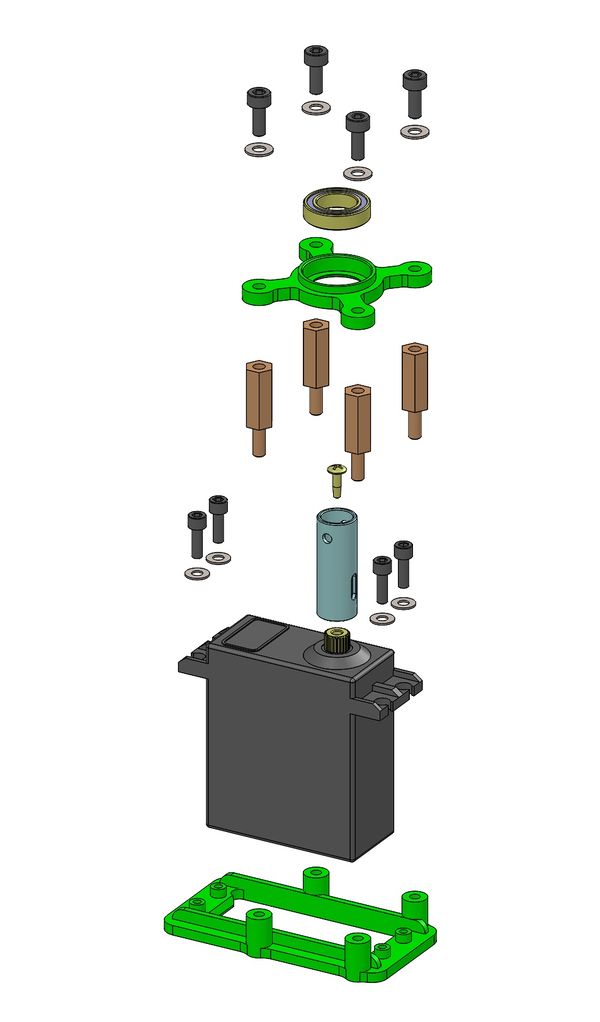

Assembly

On the Camera Mount pivot use the two Nylon M3 screws cut down so that they tighten against each other without jamming the pivot points.

|

| Upper unit assembly |

|

| Lower unit assembly |

A Video Sample

|

Test at Eldorado Dry Lake - October 2016 |

See Also

Project 3D Print Files

The following are the 3D print ZIP files used in this specific build. For more versions and information, please see my Thingiverse postings here:

Mark_q Thingiverse Designs

More P&T's

Where to buy the parts

- For the bearing and servo coupler -

- For the GWS S125-1t 25t servo -

- Global - GWS S125-1t Servo

Comments? Questions?