Difference between revisions of "3D Print Design Notes"

(→Hole Sizes) |

(→Other Common Shapes) |

||

| Line 69: | Line 69: | ||

These are tight measures on purpose. The idea is that you will follow the print up with a drill to insure the hole is appropriately sized for clearance or tapping.<br><br> | These are tight measures on purpose. The idea is that you will follow the print up with a drill to insure the hole is appropriately sized for clearance or tapping.<br><br> | ||

| − | === | + | === Hex Nut Holes === |

| − | + | Like round fastener holes I design these very tight because I want to create a "press fit" such that the nut will not fall out of the part after it is installed. The challenge here is to get the size just right so that it will accomodate the variations found in standard hardware.<br> | |

| − | + | ||

| − | + | ||

Because holes are almost always a bit small (over-extruded) I use the standard dimension given for hardware plus 0.05mm which as a general rule creates a push fit but again, this is assuming a correctly calibrated printer.<br> | Because holes are almost always a bit small (over-extruded) I use the standard dimension given for hardware plus 0.05mm which as a general rule creates a push fit but again, this is assuming a correctly calibrated printer.<br> | ||

Revision as of 20:52, 1 January 2018

December 2017

|

Introduction

To date (December, 2017) there have been well over 30,000 downloads of my parts. With that as a background, from time to time I have been asked to make adjustments to my designs because for one reason or another there is a fitment issue. Some folks have mentioned thay have to "scale-up" my prints by a few percent, others have to "scale-down".

Another issue that seems to get to some folks is the idea of tolerance. I am told that my hole sizes are too tight and that I don't design in enough "slop" to accomodate all the different print set-up variances.

Even with the fairly large number of downloads, I have been asked less than a dozen times to make these changes and for the most part I have been able to help the person resolve their real issue. Below then are some of the design ideas I follow and rarely comprimise. I hope this helps answer any questions about my parts and how they should fit.

First Things First - Printer Calibration

Nearly all printers come pre calibrated and the variance between them is extremely small. However, over time parts wear and software updates and users make changes so this is likely the most common cause of print fitment problems. The calibration process is different on different printers but the results should always be the same, an extremely accurate part.

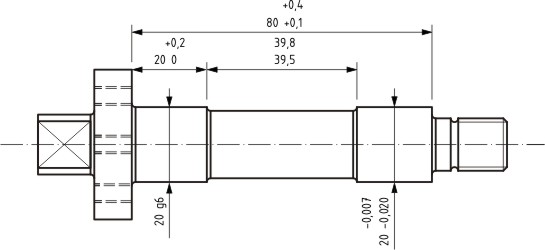

If you haven't gone through the process of checking the calibration of your printer, please do this as it will tell you whether your prints will be accurate and "as designed". One simple method is to download or create a test piece, print it and check its measurements. I use a "test cube" which is a 20mm x 20mm x 20mm x 1.5mm square tube. This will tell you whether your printer is accurately reproducing the design on all axis and additionally checks the amount of extruded filament.

All thermoplastic filaments shrink but the difference between them is very small so you should only have to calibrate once. Here are three common filament shrink rates that have been published in various technical reports:

- ABS - 0.4% - 0.9%

- PLA - 0.3% - 0.6%

- PETG - 0.2% - 0.6%

As an example this means that if you print a test cube in ABS and your printer is factory calibrated to accomodate zero shrinkage then wnen you measure the part it will be 19.82mm to 19.92mm on each side and the wall thickness will be between 1.487mm and 1.494mm. Generally this is "close enough" but if you want perfect parts - calibrate!

Dimensional Tolerance

In normal design environments, there is a standard set of design tolerances which allow a certain amount of play or slop so that production machinery can be optimized to produce consistant well fitting parts. In FDM or FFF 3D printing however the machine variances are constantly different from one printer to the next with no control by the designer to affect machine settings. All machine settings must be managed by the machine user/owner.

In addition to this, there is no tolerance built into the G-Code production which creates the part so the only consistant option is to design to exact specifications and help the user understand they will, in some cases, have to adjust the part a small amount.

Round Hole Sizes

Holes are the most common issue as most printers slightly "over-extrude" which squishes more material into the holes walls thus shrinking the hole. To alleviate this problem, first calibrate your printer as noted above and second, set your shell thickness to 1.2mm so that you can drill the hole out to its correct size without cutting through the shell thickness inside the hole.

Here are some of the designed hole sizes I use in all my designs:

| Size | Clearance Diameter | Tap Diameter |

| M2 | 2.1mm | 1.65mm |

| M2.5 | 2.6mm | 2.10mm |

| M3 | 3.1mm | 2.55mm |

These are tight measures on purpose. The idea is that you will follow the print up with a drill to insure the hole is appropriately sized for clearance or tapping.

Hex Nut Holes

Like round fastener holes I design these very tight because I want to create a "press fit" such that the nut will not fall out of the part after it is installed. The challenge here is to get the size just right so that it will accomodate the variations found in standard hardware.

Because holes are almost always a bit small (over-extruded) I use the standard dimension given for hardware plus 0.05mm which as a general rule creates a push fit but again, this is assuming a correctly calibrated printer.

Since you can't resize these holes with a drill, the easiest way to fix a tight fit is to heat a nut with a lighter or small torch and then push it into the hole. Be careful not to overheat the nut as this can miss-shape the hole.

See Also