Difference between revisions of "Laser GCODE Conversion Method"

(→Introduction) |

(→CAD Work to get a DXF) |

||

| Line 16: | Line 16: | ||

=== CAD Work to get a DXF === | === CAD Work to get a DXF === | ||

| + | |||

| + | If you have a CAD package which has the ability to design solid parts, create a virtual assembly and create/save DXF drawing files then this method will work for you. This method will also work if you do not have a CAD setup but do have the ability to get DXF drawings of your parts. I have a SolidWorks professional package which is a bit high-end for typical hobbyists but there are inexpensive and even free alternatives which can do this work quite easily. If you do not have a CAD setup, three are listed below that can get you there inexpensively<br> | ||

| + | |||

| + | '''Three CAD packages:'''<br> | ||

| + | |||

| + | :* <u>'''[https://www.autodesk.com/products/fusion-360/personal Fusion360 for Hobbyists]'''</u> by Autodesk is excellent and free | ||

| + | :* <u>'''[https://www.onshape.com/en/ Onshape is another free for Hobbyist platform which can do it all | ||

| + | :* <u>'''[https://www.solidworks.com/solution/3dexperience-solidworks-makers SolidWorks for Makers]'''</u> is an online version that costs $9.99/month<br> | ||

| + | |||

| + | Of these three, Fusion360 is likely the easiest to learn for most folks without CAD experience.<br> | ||

In my CAD design software (SolidWorks in my case) after completing all part design I layout all similar thickness parts in an assembly, fitting them to virtual 4" x 36" balsa sheets. | In my CAD design software (SolidWorks in my case) after completing all part design I layout all similar thickness parts in an assembly, fitting them to virtual 4" x 36" balsa sheets. | ||

Revision as of 15:32, 3 February 2023

| |

Introduction

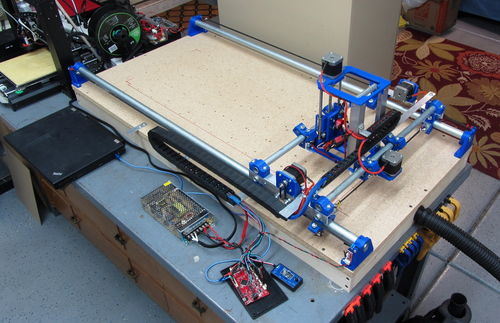

I've been improving my ability to use my Bench-top Laser to cut balsa and plywood parts for some scratch build RC projects I have been doing. Some of the improvements have been on the machine itself now with a more powerful laser (10w), better stepper motors and drivers, air assist, etc. Other improvements have been in the method I use to create the gcode files needed to cut these parts. This article then is about the process I use to create these files.

CAD Work to get a DXF

If you have a CAD package which has the ability to design solid parts, create a virtual assembly and create/save DXF drawing files then this method will work for you. This method will also work if you do not have a CAD setup but do have the ability to get DXF drawings of your parts. I have a SolidWorks professional package which is a bit high-end for typical hobbyists but there are inexpensive and even free alternatives which can do this work quite easily. If you do not have a CAD setup, three are listed below that can get you there inexpensively

Three CAD packages:

- Fusion360 for Hobbyists by Autodesk is excellent and free

- [https://www.onshape.com/en/ Onshape is another free for Hobbyist platform which can do it all

- <u>SolidWorks for Makers is an online version that costs $9.99/month

Of these three, Fusion360 is likely the easiest to learn for most folks without CAD experience.

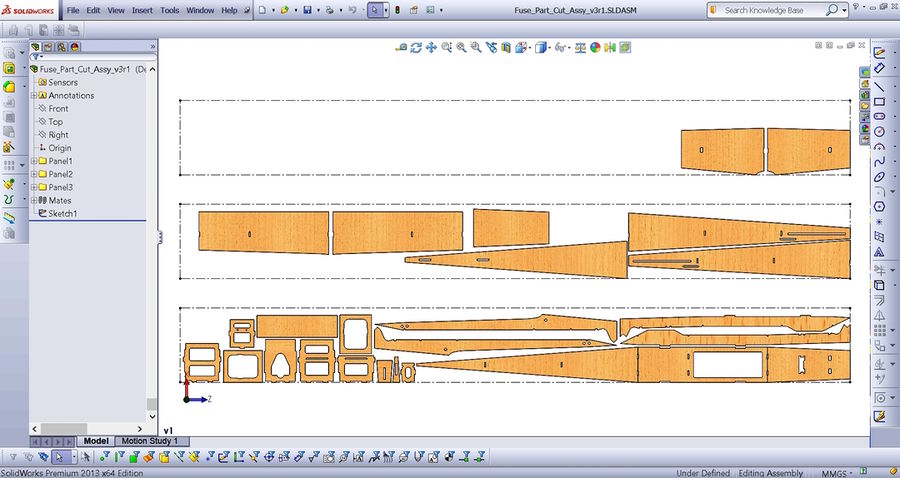

In my CAD design software (SolidWorks in my case) after completing all part design I layout all similar thickness parts in an assembly, fitting them to virtual 4" x 36" balsa sheets.

|

| All components laid out on three virtual panels |

In the above example I have laid out all the parts of a fuselage build within three 4" x 36" virtual panels represented by the dashed boxes. Once the layout is done I group each set of panel components into three folders to represent the three panels. This gives me the ability to suppress the panel groups so I can send just one to a DXF drawing.

|

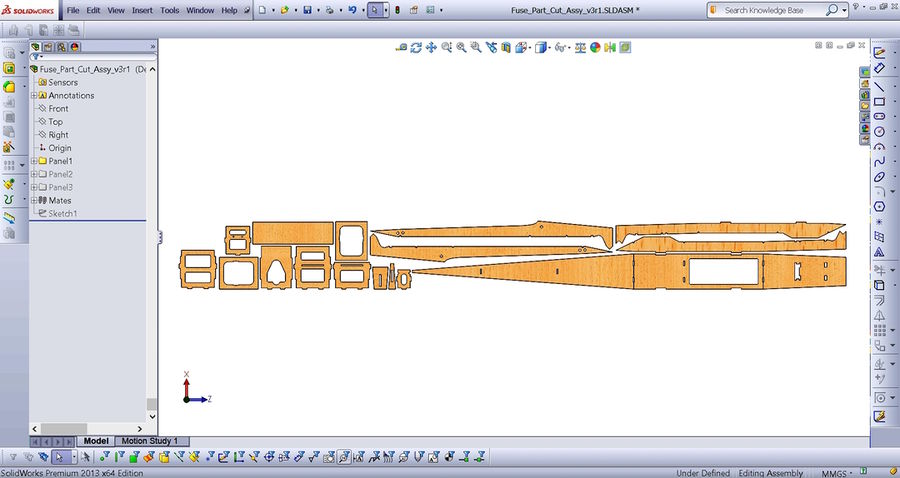

| Two panels and the boxes suppressed |

I then (in SolidWorks) create a drawing from this assembly making the drawing size 4" x 36" and set the X and Y axis to the part edges.

|

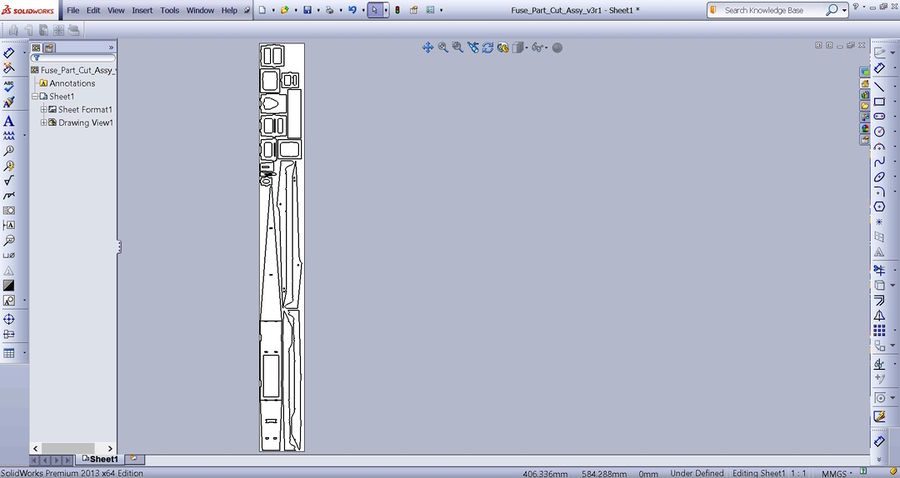

| Drawing ready to save to DXF |

Once this is done I save the drawing as a DXF. I then go back and suppress this first panel and un-suppress the next panel, saving it as the next DXF. Note: I also suppress the dashed box as it is not needed in the DXF file.

I am now ready to convert these three DXF files to a workable gcode file.

DXF to GCODE

In my method there are a couple of steps to this conversion using four free tools.

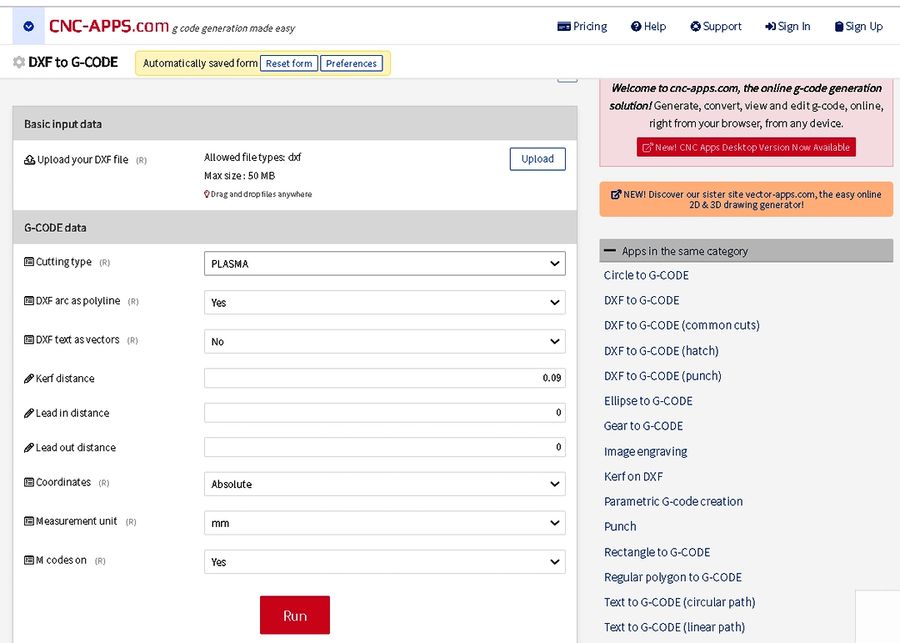

Step one is to upload each DXF to an online conversion tool to create get a generic gcode file. I use the free online converter found at "CNC-APPS.com". It is very easy to use and in my experience, has never written a bad or missed instruction.

Link: DXF to GCODE Converter

Below is a screenshot of the DXF to GCODE converter with the parameters set for a plasma or laser cutter.

|

Once the parameters are set, click on the "RUN" button and in a few seconds (up to a minute) three file types are offered for download. I use the "GCODE" file type.

Step two is all about editing/check/clean-up. You can edit the file in any text editor. I use "Notepad++". This is a really nice code editing tool that I have written macros in to do all the GCODE file edits.

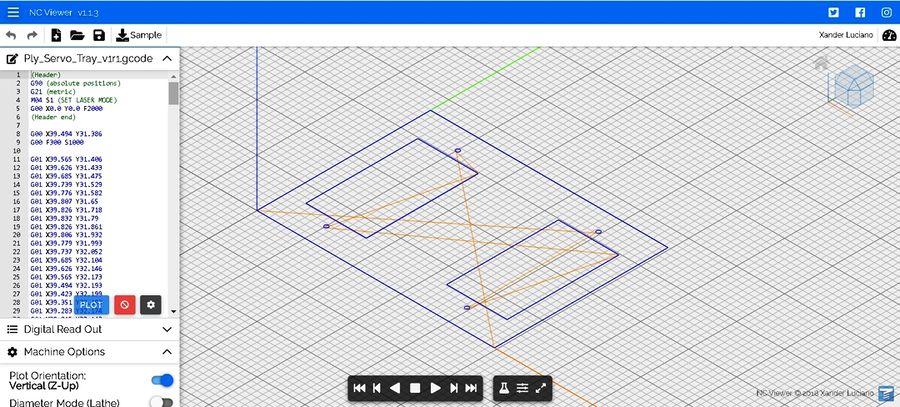

For the check part of this step, I use the free web based simulator "NC Viewer" at NCVIEWER.com

|

Upload your edited gcode file and hit the play button. You can watch the cut sequence while it draws through your shapes. The different colored lines represent paths for laser-off transit (Red) and laser-on cut (Blue). This is the clean-up part of this step and is a great way to check the quality of your gcode and isolate areas where you may want to make other changes.

RunIt!

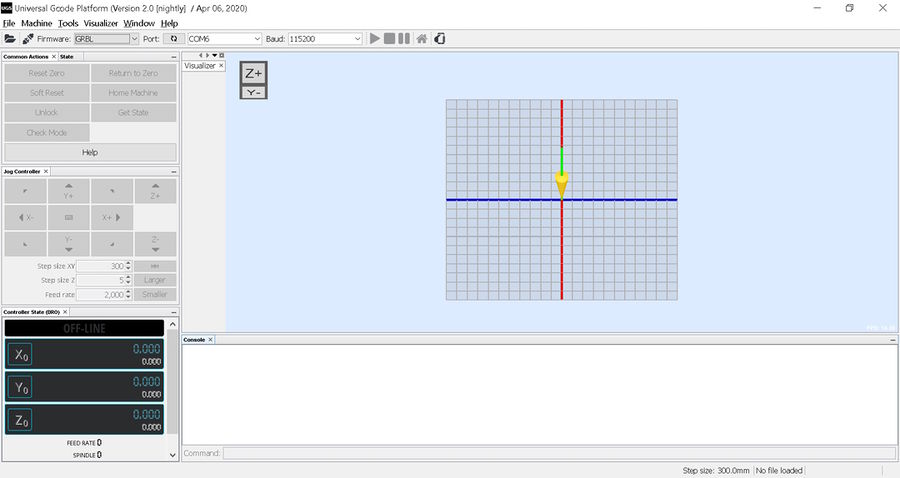

File should be ready to send to the laser. In my case I use UGS Platform which is another awesome freebie...

|

See Also

Referenced Links