Difference between revisions of "Grom Audio Toyota Microphone Mount"

(Created page with "<i><small>© Mark Qvale - October, 2018</small></i><br> {| cellspacing="1" cellpadding="1" width="95%" border="0" |- | align="left" valign="top" width="30%" | __TOC__ | align...") |

(→Part Design) |

||

| Line 23: | Line 23: | ||

{| border="0" cellspacing="1" cellpadding="1" align="center" | {| border="0" cellspacing="1" cellpadding="1" align="center" | ||

|- | |- | ||

| − | | align="center" | [[File:tmm1.JPG| | + | | align="center" | [[File:tmm1.JPG|500px]] |

| − | | | + | |- |

| − | | align="center" | | + | | align="center" | Printed part and blank cover |

|} | |} | ||

<br> | <br> | ||

| Line 32: | Line 32: | ||

|- | |- | ||

| align="center" | [[File:tmm6.gif|600px]] | | align="center" | [[File:tmm6.gif|600px]] | ||

| − | |||

| − | |||

|} | |} | ||

<br> | <br> | ||

| Line 40: | Line 38: | ||

|- | |- | ||

| align="center" | [[File:tmm7.JPG|600px]] | | align="center" | [[File:tmm7.JPG|600px]] | ||

| − | | | + | |- |

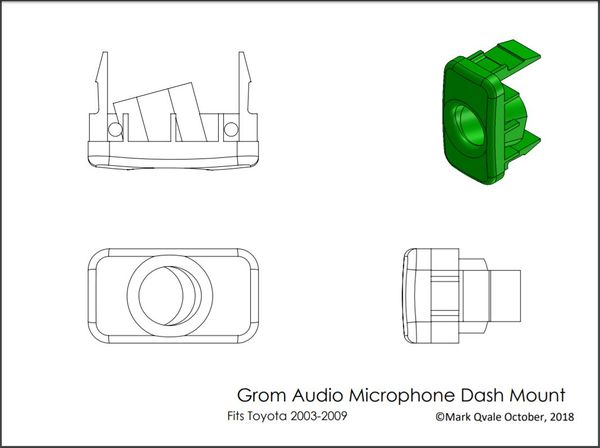

| align="center" | Part sketch | | align="center" | Part sketch | ||

|} | |} | ||

Revision as of 22:10, 28 October 2018

© Mark Qvale - October, 2018

| |

Introduction

I bought a Grom Audio bluetooth module for my 2007 Toyota 4Runner and while the unit itself is excellent, I decided I didn't like the microphone mount. I've installed similar microphone mounts in the past and always found them to be unreliable, especially where I live in Southern Nevada where we see inside temperatures of 150 degrees F (65C) or more as a common occurrence in the summer. Simply put, the double sided tape just disintegrates.

This then is a small project to crate a 3D print part to mount the microphone in a more permanent piece with a more "factory" look.

Part Design

I modeled the part after one of the blank snap-in switch covers. The microphone slides into the back of the piece and is held in by a slight interference fit and a couple tiny dabs of hot glue which also makes it easily removable. It is angled up 15 degrees so that it is essentially pointed at the driver

|

| Printed part and blank cover |

|

|

| Part sketch |

Print Setup

This piece, as shown, is printed in black ABS at a print resolution of 0.1mm. It is sliced and printed on its side with a support structure set up as follows:

- Slicer - Cura

- Overhang Angle - 70°

- Support infill - 24%

Here is a picture of how it looks in Cura:

| 700px | Sliced view |

See Also

3D Print File

Comments? Questions?