Difference between revisions of "DIY - Vacuum Forming Box"

From ItsQv

(→Frame Build) |

(→Frame Build) |

||

| Line 114: | Line 114: | ||

{| border="0" cellspacing="1" cellpadding="1" width="800" align="center" | {| border="0" cellspacing="1" cellpadding="1" width="800" align="center" | ||

|- | |- | ||

| − | | align="center" | [[File:VF21.JPG| | + | | align="center" | [[File:VF21.JPG|600px]] |

|- | |- | ||

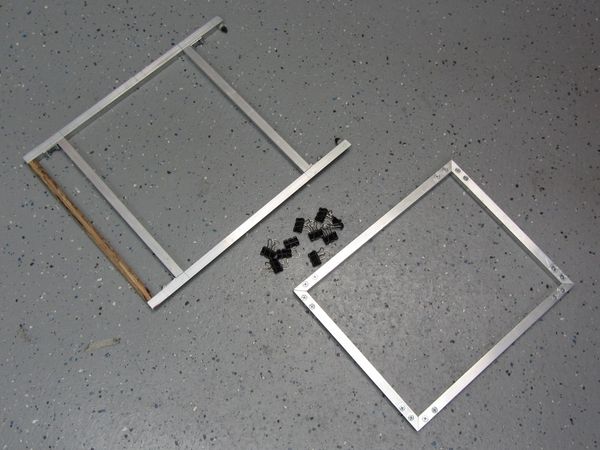

| align="center" | Aluminum frame components | | align="center" | Aluminum frame components | ||

| Line 122: | Line 122: | ||

{| border="0" cellspacing="1" cellpadding="1" width="800" align="center" | {| border="0" cellspacing="1" cellpadding="1" width="800" align="center" | ||

|- | |- | ||

| − | | align="center" | [[File:VF22.JPG| | + | | align="center" | [[File:VF22.JPG|600px]] |

|- | |- | ||

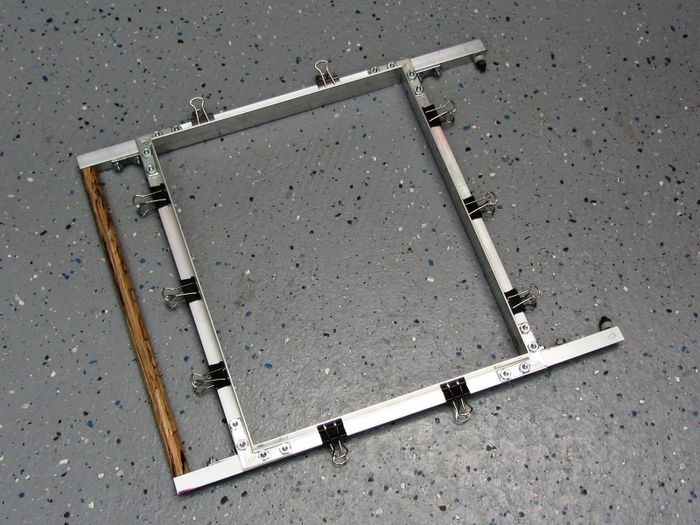

| align="center" | Clamp frame corner detail | | align="center" | Clamp frame corner detail | ||

| Line 130: | Line 130: | ||

{| border="0" cellspacing="1" cellpadding="1" width="800" align="center" | {| border="0" cellspacing="1" cellpadding="1" width="800" align="center" | ||

|- | |- | ||

| − | | align="center" | [[File:VF23.JPG| | + | | align="center" | [[File:VF23.JPG|600px]] |

|- | |- | ||

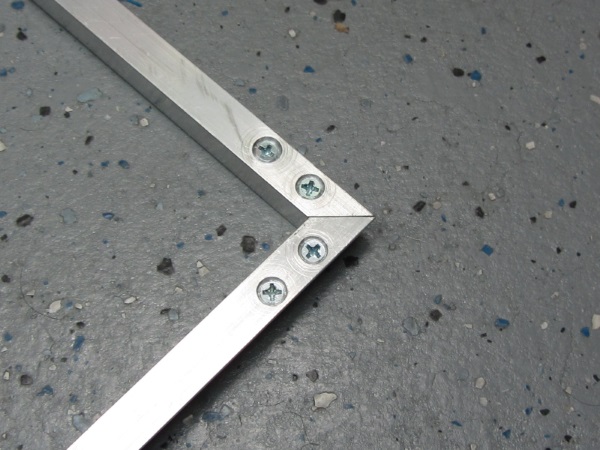

| align="center" | Main frame joint detail | | align="center" | Main frame joint detail | ||

| Line 138: | Line 138: | ||

{| border="0" cellspacing="1" cellpadding="1" width="800" align="center" | {| border="0" cellspacing="1" cellpadding="1" width="800" align="center" | ||

|- | |- | ||

| − | | align="center" | [[File:VF24.JPG| | + | | align="center" | [[File:VF24.JPG|600px]] |

|- | |- | ||

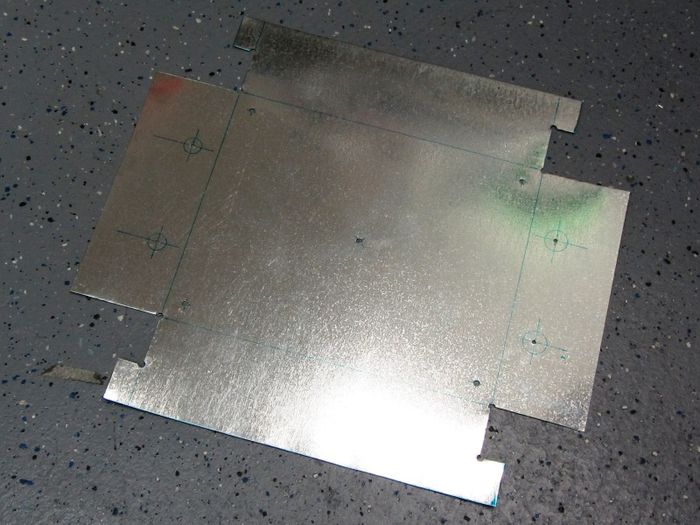

| align="center" | Completed frames | | align="center" | Completed frames | ||

Revision as of 00:34, 6 June 2018

© Mark Qvale - June, 2018

| |

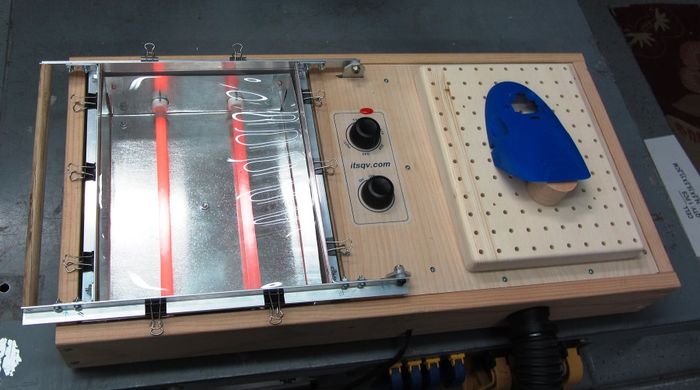

| New DIY Tool |

Introduction

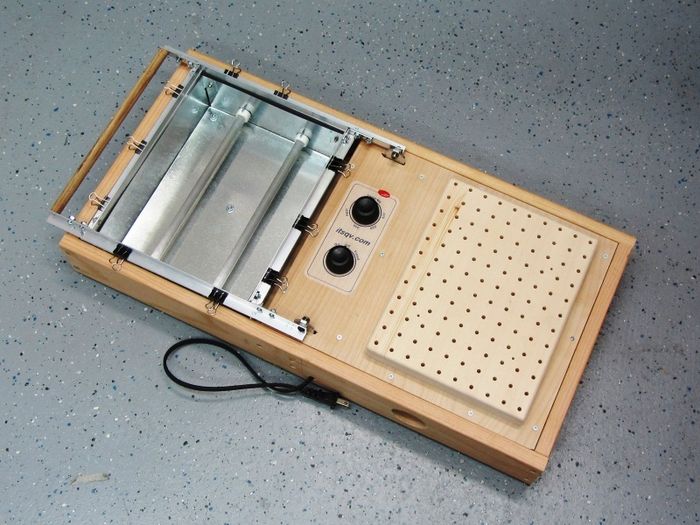

After doing hundreds of 3D prints for canopies, skids, shields, et., I decided to build my own Vacuum Forming box so I could get the weight dramatically down on some these parts. I did a pile of research and found many different styles and sizes but finally decided to simply take the things I liked in many pictures found on google and design my own. This then is my version.

Tools I Used

Besides the basic hand tools, these power tools helped immensly with keeping things sized and squared perfectly.

- 1. 10" Chop saw w/60 tooth carbide blade

- 2. Drill press

- 3. 10" Table saw

Parts & Pieces

Here is the complete parts list for this project. All dimensions and screw specs for this project are imperial (inches).

Cut List

- Hardwood 3/4 x 2-3/4 x 11-1/2

- Hardwood 3/4 x 3-1/4 x 24

- Hardwood 3/4 x 3-1/4 x 11-1/5

- Hardwood 5/8 x 1-1/2 x 2

- Hardwood 3/4 x 2-3/4 x 10

- Hardwood 3/4 x 2-3/4 x 10-1/8

- Plywood 15/64 x 11-1/2 x 24

- Plywood 15/64 x 11-1/2 x 14

- Pine Laminate 1 x 8 x 10

- Alum Flatbar 1/8 x 1 x 3-1/2

- Alum Angle 1/16 x 1/2 x 1/2 x 14L

- Alum Angle 1/16 x 1/2 x 1/2 x 10-1/2L

- Alum Angle 1/16 x 1/2 x 1/2 x 9-1/2L

- Alum Angle 1/16 x 1/2 x 1/2 x 11-1/4L

- Wood Dowel 1/2D x 10-1/2L

- Heat Box 2-3/4 x 10-3/16 x 8-7/16

Hardware

- 4x #8 x 1-1/4" wood Screws

- 12x #4 x 3/4" wood screws

- 4x #8-32 x 2" round head machine screws

- 5x #8-32 x 1" pan head machine screws

- 20x #6-32 x 3/8" flat head machine screws

- 8x #6-32 x 3/8" pan head machine screws

- 2x #12-24 x 3/4" button head machine screws

- 9x #8-32 hex nuts

- 28x #6-32 hex nuts

- 2x #12 nylok hex nuts

- 14x #8 flat washers

- 2x 3/16 x 3/8 x 3/16 nylon spacers

- 8x small steel flat corner brackets

Heater Components

- Walmart Toaster Oven

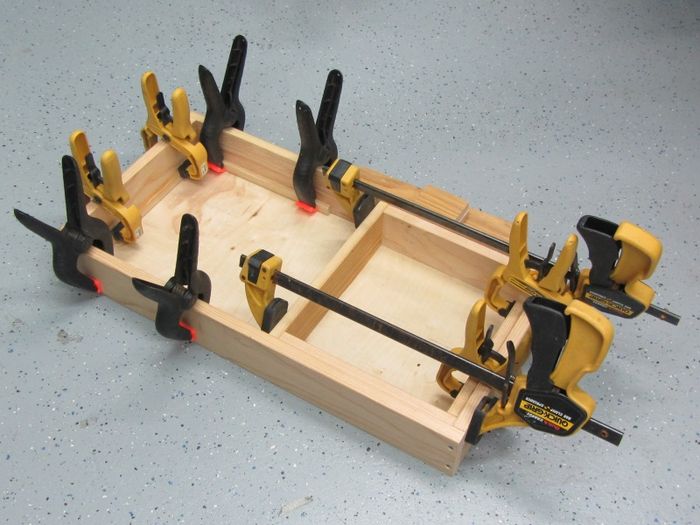

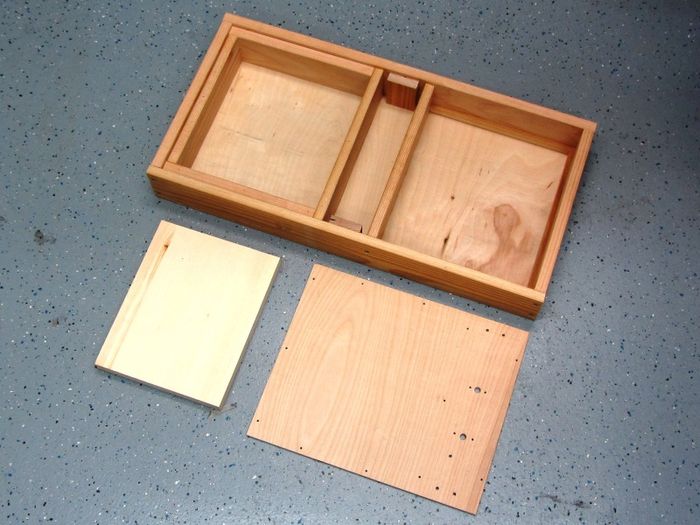

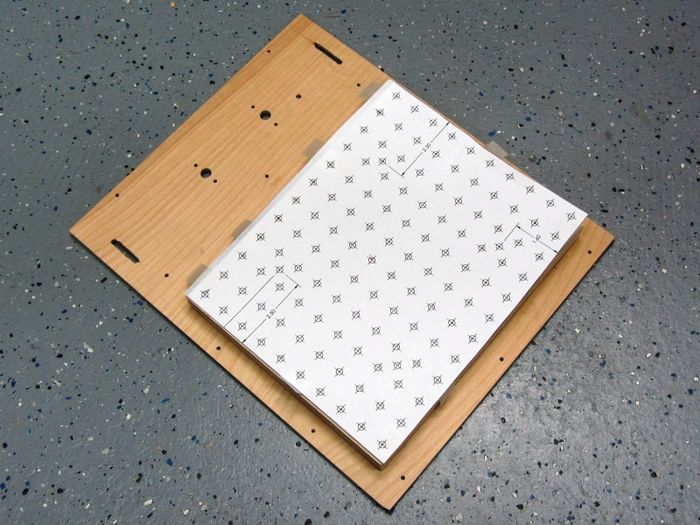

Base Build

|

| Cut wood pieces and box build |

|

| Corner clamps |

|

| Box build |

|

| Box and top parts |

|

| Template for marking and drilling the vac holes |

Frame Build

|

| Aluminum frame components |

|

| Clamp frame corner detail |

|

| Main frame joint detail |

|

| Completed frames |

|

| Completed and mounted frames |

Heat Box Build

|

| Initial selected components |

VF31 VF32 VF33 VF34

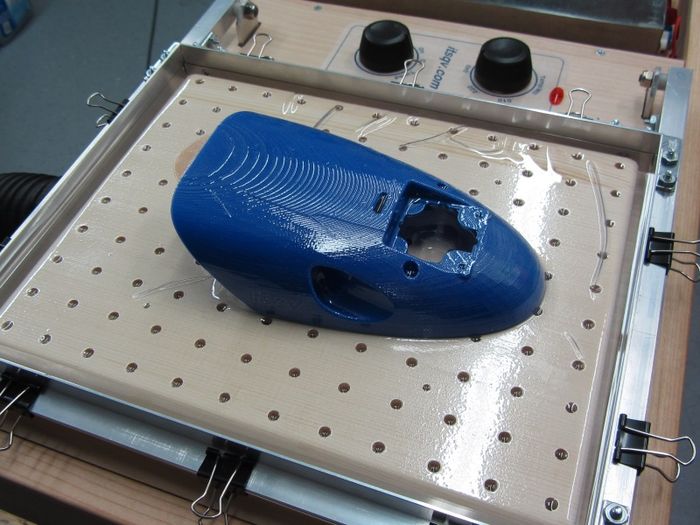

First Mold!

|

| Wait for it! |

|

| What's that sucking sound? |

|

| A very light, near perfect replacement part! |

VF51 VF52 VF53

See Also

TBA