Difference between revisions of "Lightweight Pan and Tilt"

(→Project 3D Print Files) |

(→See Also) |

||

| (3 intermediate revisions by the same user not shown) | |||

| Line 126: | Line 126: | ||

== See Also == | == See Also == | ||

| + | <br> | ||

| + | :* [[ 390 Degree Geared Pan and Tilt]] | ||

| + | :* [[Forward Offset Pan %26 Tilt]] | ||

| + | :* [[Heavy Duty Pan and Tilt]] | ||

| + | :* [[Gimbals,_Mounts_and_Controllers | Gimbals!]] | ||

| + | <br> | ||

=== Project 3D Print Files === | === Project 3D Print Files === | ||

| Line 139: | Line 145: | ||

<br><br><br> | <br><br><br> | ||

| − | [[Category: | + | [[Category:Contents]] |

| − | [[Category: | + | [[Category:Gimbals]] |

Latest revision as of 18:06, 10 March 2017

| |

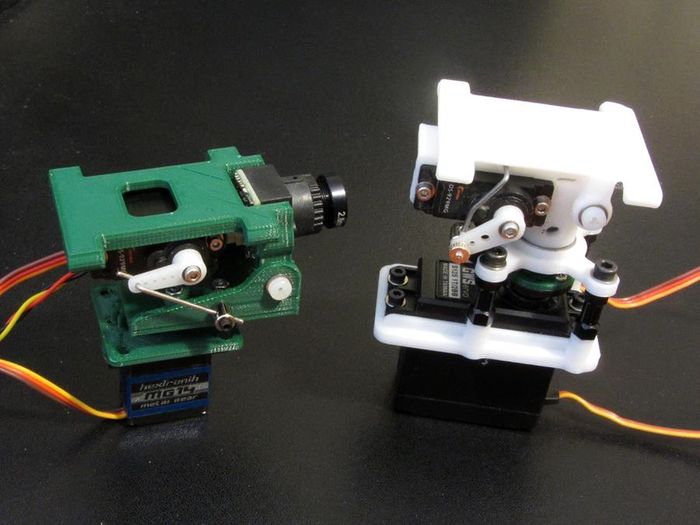

| Smaller and Stronger |

Introduction

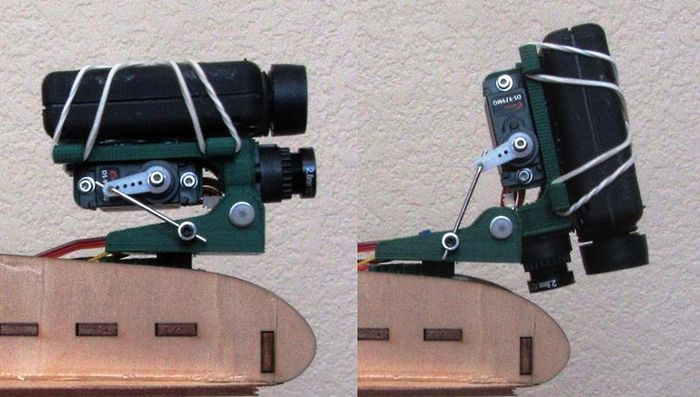

Been waiting for someone to come out with a 12-20 gram 360 degree servo to use for a pan and tilt for some time now. The idea was to build a similar Pan & Tilt to my Heavy Duty unit but with hopefully half the weight. Well I didn't find a smaller 360 servo but I have put together a lightweight unit (51g) that is more robust than any of the small units I have purchased and tried.

|

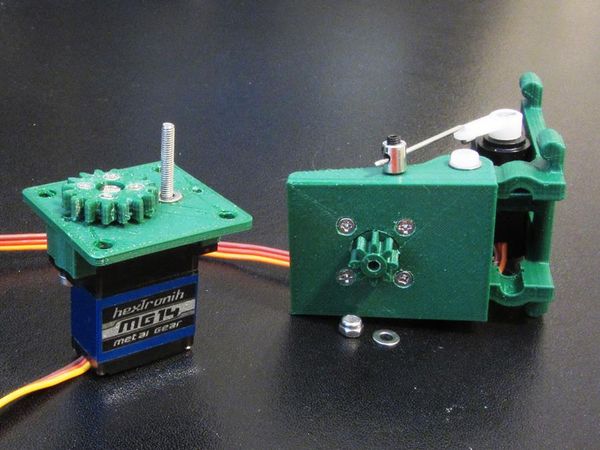

| Lightweight and Heavy Duty Pan & Tilts |

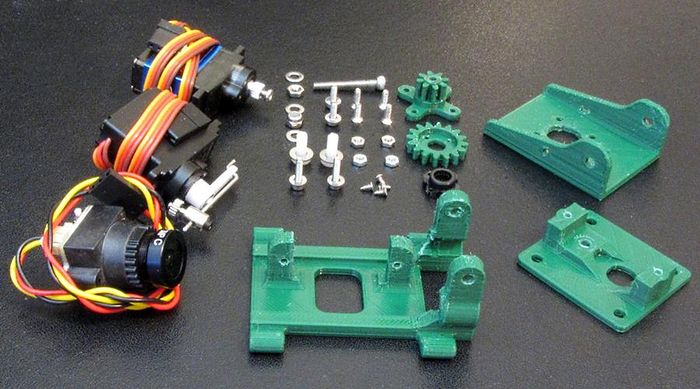

This project started with store bought gears which are very well made and smooth. The issue is getting them attached perfectly to the servo spline and camera mount so there is no wobble or gear-train binding. To solve this I found a gear generator that works in my CAD program which gives me the ability to create printable high quality gears with the features needed to make the attachments. Of course it requires a fairly high resolution printer, 0.1mm or finer, to print these pieces succesfully.

|

So, with a gear train I can now make a beefier small Pan & Tilt that will rotate up to 360 degrees or more.

Parts & Hardware

|

Hardware:

- 4x #1 x 1/8 Flat Head Self Tapping screw

- 4x M2 x 6mm Socket head machine screw

- 4x M2 Flatwasher

- 4x M2 x 6mm Flathead machine screw

- 4x M2 Hex nut

- 1x M2.5 x 20mm Socket head machine screw

- 3x M2.5 Flatwasher

- 1x M2.5 Hex Nut

- 1x M2.5 Nyloc Nut

- 2x M3 x 8mm Philips head machine screw

- 2x M3 Flatwasher

- 0.047" x 50mm Steel wire

- Servo wire connector

Printed Parts:

- LWPT Servo Plate

- LWPT Pinion Gear 8T

- LWPT Drive Gear 16T

- LWPT Camera Mount Base

- LWPT Camera Bracket

Servo Selection:

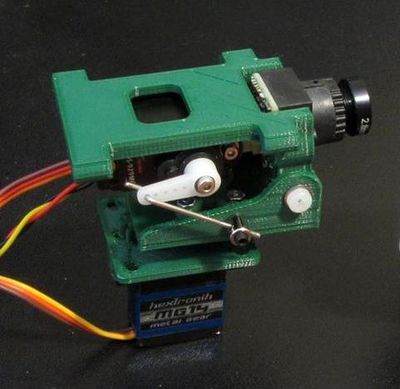

Pan Servo - I originally built this to fit the TowerPro MG90S because it is a very popular servo. It happens that it also fits a Hextronic MG14 digital servo which is a little stronger. With both of these servos the total sweep angle is 265 degrees. Both servos can be modified with a couple of resistors to get the full 360 degrees if you need the extra sweep. See YouTube for directions on the servo mods.

Neither of the two servos above have great resolution so if you have a particular servo that you like, drop me a line at the contact link at the bottom of this page. You can also use the HobbyKing 180 degree servo to get the full 360 sweep but this servo has a lot of horrible reviews so I leave that up to you to decide.

Tilt Servo - Many of the current 9-12 gram servos will fit the tilt plate. A Corona DS929MG is shown.

Weights and Measures

Weights are "as shown" with the MG14 and DS929MG Servos and all wires.

- Original Heavy Duty Pan and Tilt - 98g

- Lightweight Pan and Tilt - 51g

- Lightweight Pan and Tilt w/FPV - 66g

Gear Ratio - 1:2

Print and Dimension Info

It is important that a high quality resolution, 0.1mm or better, be used when printing the gears and the Servo Plate. Also, keep the print speed very slow. The parts shown here are all done in PLA.

The Servo Plate has a critical dimension between the small gear pivot and the large spline hole. It is critical in that if it is too tight the gears will not rotate and if it is too loose, the gears will become sloppy. Currently the dimension between these two holes is 12.35mm. You may have to modify this dimension depending on your print quality.

Configurations

This P&T can have two configurations, one with just the tilt plate which should work with the Mobius, Mobius Mini, Foxear and Runcam style cameras. The second configuration includes a simple FPV camera snapped into the integrated mount. The FPV camera shown is a 1000TVL Banggood camera which is 17mm square.

|

| With FPV Camera snapped in place |

Assembly

|

- 1. Assemble the Small Gear pivot bolt, large gear and Pan Servo on the Servo Plate

- 2. Assemble the Small Gear, Mount Base, Camera plate and Tilt Servo

- 3. Mount the Servo Plate assembly on the plane

- 4. Add the Large Gear and tilt assembly

- 5. Test and Fly!

A Video Sample

TBA

See Also

Project 3D Print Files

The following are the 3D print ZIP files used in this specific build.

Comments? Questions?